This Northeastern researcher is hacking genomes to grow plastic and feed astronauts

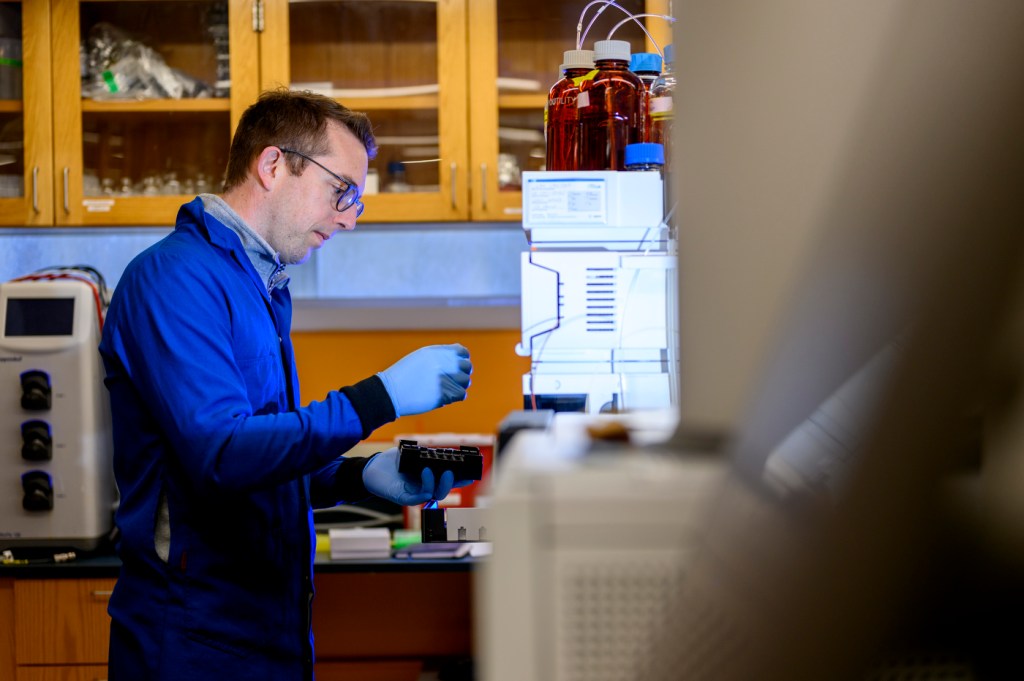

Assistant professor of chemical engineering Benjamin Woolston has received funding from the Office of Naval Research to support his research hacking Clostridia to produce everything from food to plastic.

Benjamin Woolston hacks microbes.

An assistant professor of chemical engineering at Northeastern University, Woolston engineers microorganisms so that, “instead of the cell doing what it wants to do, we get it to do something that we want it to do,” he says.

Right now, that means making “precursor molecules,” Woolston says.

Precursor to what? Everything from “complex, food-type molecules” to “things that could be used to make rubber, or make plastic.”

A microbial cell, he says, takes “in nutrients from its surroundings, from its media. It has enzymes encoded within its genomes, basically converting those compounds to generate energy for itself to survive. It’s generating more of itself.

“We try to manipulate all those reactions.”

Woolston recently received the 2025 Young Investigator Award from the Office of Naval Research (ONR) for his project, called “Expanding the Product Range of Anaerobic Methanol Fermentation.”

“But why is the Navy interested in this?” he asks — rhetorically — with a laugh.

Ethanol is going out of fashion

The short answer is that ethanol, a primary component in the fuel of many vehicles, from cars to naval vessels, is far from sustainable — 40% of arable land in the United States is currently earmarked for bioethanol fuel production, Woolston says.

But as the global population continues to grow, Woolston continues, we will “need to double current agricultural production” by 2050, according to the World Health Organization.

So “why are we using the best land we have,” Woolston asks, “the best growing areas and best growing conditions, to produce something that’s going to end up making a fuel that’s burned in an automobile engine?”

But methanol — a chemical cousin to ethanol — can be made by other means, including through electric catalysis, “where you use electricity, react it with CO2, and one of the things you can make from that is methanol,” Woolston says.

In other words, a fuel byproduct — carbon dioxide, one of the primary drivers of climate change — can be pulled out of the atmosphere and used to make fuel again, closing an unsustainable loop in favor of a sustainable one.

As methanol grows in availability, the Navy is actively researching new ways of fueling its ships with it, Woolston says.

And plentiful, sustainable methanol makes a perfect opportunity for Woolston’s microbes, which consume methanol.

The microbes Woolston uses in his lab — Clostridia, a variety of bacteria — “are not the traditional biotechnology workhorses,” Woolston says. For one, they are anaerobic, which means they do not require oxygen to survive.

In fact, oxygen is poisonous to these microorganisms, which can make working with them particularly challenging.

Editor’s Picks

New techniques for new applications

“A lot of what we do is focused on developing tools,” Woolston says. “We have to work in anaerobic glove boxes.”

The work often involves integrating large pieces of DNA into the Clostridia genome. In more widely used bioengineering microbes — like Escherichia coli (more commonly “E. coli”) — that’s pretty easy, Woolston says.

“But we had to come up with new ways for the microbes we work with. We needed new techniques.”

Proving that those techniques work is what led to interest from the Office of Naval Research. “We’ve basically spent the last four to five years building the tools,” Woolston says. “With this ONR project, we’re now saying, ‘OK, we’ve got the tools, let’s go and do what we’ve always wanted to do.’

“Which is actually make the products, and convert methanol into these targets.”

Woolston notes that, “essentially what you’re making is a protein-based biomass,” which means that any number of materials can be derived from that biomass, from plastics to foods.

Woolston’s research will directly benefit the kind of long-term missions carried out by the Navy.

“Let’s say you’ve got an aircraft carrier that’s going to be deployed for a month or two without setting foot in a port,” Woolston suggests. “If the fuel they were carrying on board to power the ship,” i.e., methanol, “could also be used to make the other things they needed,” like food or even replacement parts, that dramatically reduces the strain on supply lines.

But it doesn’t stop at naval applications. Any significantly isolated group of people could benefit — from Antarctic researchers to astronauts.

“One of the new and exciting directions for metabolic engineering and synthetic biology is this idea of space exploration,” Woolston says. “Rather than having to send astronauts into space with everything they need — all the drugs, all the food and everything — could you give them different freeze-dried packets of different bacteria?”

“When you want your antibiotic, grow this one, and it will produce something for you. When you want your plastic, grow this one.”