Robots in the warehouse?

This Northeastern co-op has the blueprint

Northeastern graduate student Yash Phalle was instrumental at his co-op at Warp, a warehouse logistics company, in bringing in an autonomous forklift for pallet moving.

The electric motors echo through the warehouse as an autonomous forklift moves between tall stacks of pallets. The forklift scans its surroundings and plots a path through the aisles lined with inventory.

Guided by a digital map, the forklift goes about its work of loading and moving pallets. The operation looks like it runs by itself, but every movement is deliberate, calculated and data-driven with sensors, software and artificial intelligence. All brought together by Northeastern University graduate student Yash Phalle.

He completed the work this summer while on co-op with Warp, a Los Angeles-based software and logistics company.

Phalle’s assignment seemed simple on its face. The company was looking to automate parts of its pallet-moving process at its less-than-truckload facilities. It’s a process that involves multiple human workers, explains Daniel Sokolovsky, Warp’s CEO and co-founder.

“Our warehouses have three functions — unload, store and load,” he says. “What we wanted to do for our first robot was to handle the storage portion.”

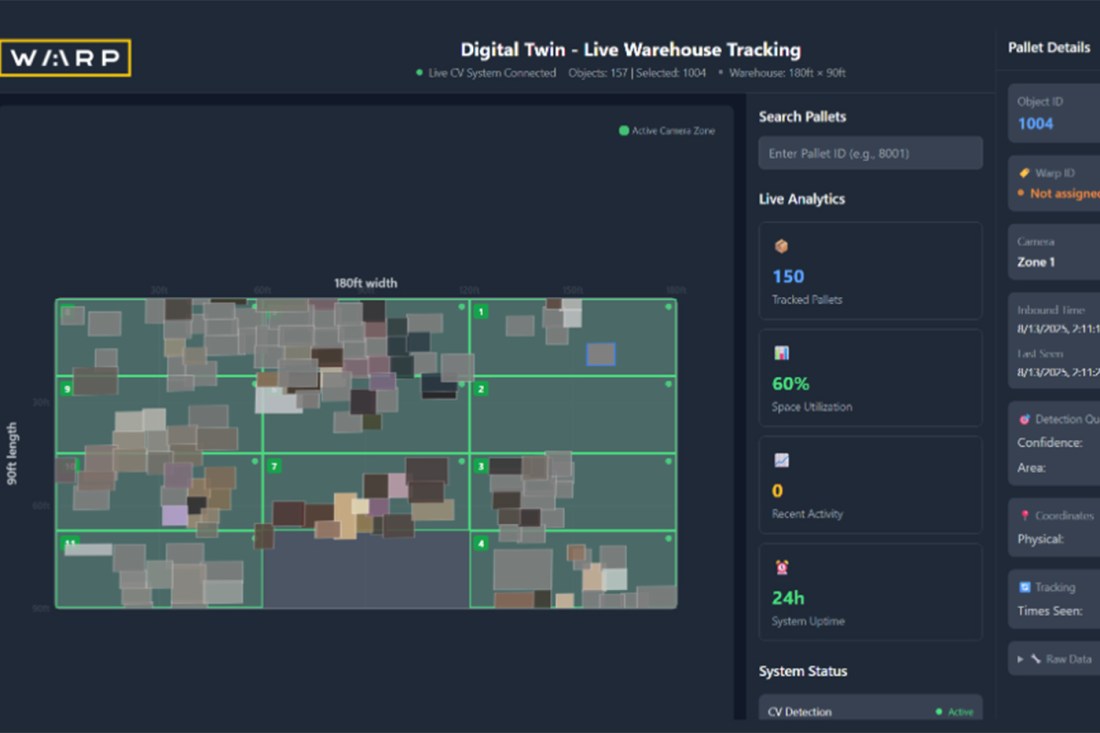

Phalle was instrumental from the start, Sokolovsky explains, helping from initial ideation to the development of its digital twin models — simulated 3D models of the warehouse — and computer-vision technology stack.

Working at the company’s prototyping warehouse in Los Angeles, Phalle hit the ground running on his first day.

Editor’s Picks

The first step was developing a digital twin replica of the warehouse, which Phalle wagers is roughly the size of Snell Library on Northeastern’s Boston campus — dimensions that are on the smaller end of the company’s various warehouses.

That was key in creating a digital environment for the robot to reference while navigating, he said — a literal digital version of the warehouse’s various columns and appropriate pallet locations.

Then came the robot dog — a robotic quadruped that Phalle installed with a 360-degree lidar sensor to roam around the warehouse, essentially serving as the vision system’s eyes on the ground.

“The main purpose of the robot was to go across the warehouse, scan it and identify any potential concerns that we need to mitigate and report,” says Phalle.

From there came the autonomous forklift, which, thanks to Phalle’s previous work, was able to navigate through the warehouse following exact coordinates, he says.

While Phalle’s co-op just about ended by the time the autonomous forklift came into the picture, Sokolovsky says the company has begun implementing it at its testing facility.

“The computer vision system that he started building fully works and is fully integrated,” says Sokolovsky. “The robot is now integrated into the computer vision system and we are able to control it through the computer vision system.”

The next step is to develop a way for the robot to work fully autonomously. Right now, the company is able to control the robot remotely with a few simple clicks.

But none of that would have been possible without Phalle, he says.

“He really helped us start this whole robotics program,” says Sokolovsky. “It didn’t exist before Yash came.”