From diabetes research to EV battery development, Northeastern co-op transfers microscopy skills across industries

Northeastern senior bioengineering major Cameron D’Mello worked as a lab researcher at Beth Israel Medical Center in Boston then at QuantumScape, a battery manufacturing company based in San Jose, California.

OAKLAND, Calif. — There are many good reasons to study things up close. Cameron D’Mello has discovered two.

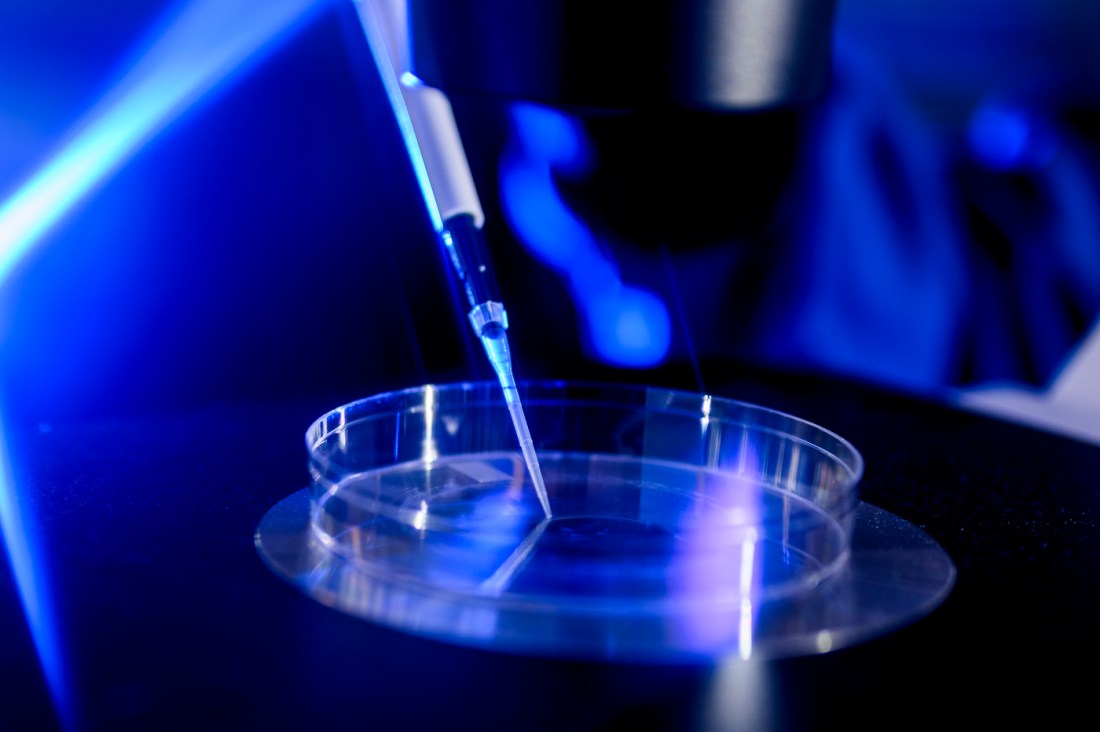

A senior bioengineering major at Northeastern University, D’Mello worked as a lab researcher at Beth Israel Medical Center in Boston during her first co-op. She examined bone samples from diabetes patients using CT scans and microscopy, and compared them to samples from people who don’t have diabetes.

Her research question — does Type 1 diabetes increase the likelihood of hip and spine fractures? To her surprise, the same tools and techniques are used to find flaws in EV car batteries.

For her second co-op, D’Mello worked at QuantumScape, a battery manufacturing company based in San Jose, California. Working with optic and laser microscopy, as well as X-rays and CT scans, D’Mello analyzed components of batteries and superchargers.

“I realized that there was a lot of interconnection in terms of trying to find defaults, trying to find issues and then utilizing that information to try to derive some significant difference and how we can apply that,” she says. “It was very much a transfer of skills.”

A native of New Jersey, D’Mello appreciates spending six months in California. Her role at QuantumScape gave her a chance to apply research and microscopy skills to a tangible product.

“I really enjoyed the process of research from my previous co-op,” she says. “But taking a step further and working with a physical product was an evolution that I wanted to achieve.”

The bone density research D’Mello contributed to at Beth Israel is ongoing, using data that she helped generate while scanning cadaver bone samples for anomalies. Using microscopy and CT scans, she analyzed bone tissue looking for trends related to diabetes and bone degeneration. It isn’t any easy connection to make, she says.

Editor’s Picks

“A lot of these individuals have things like osteoporosis and many of them were over 65,” D’Mello says, “so it’s difficult to completely make the correlation.”

At QuantumScape, D’Mello’s team focused on a different set of very tiny objects and had different objectives. But the research tools were very similar. Using microscopy, D’Mello analyzed solid-state separators — the component in an electric vehicle’s lithium battery that controls battery function long term.

After observing how the separators worked over a weeklong cycle, D’Mello reported issues that arose to the company’s research and manufacturing teams.

“It was an interesting position, being in the midway point between the research and development sides and communicating issues in different ways,” she says, “about what changes can we make in future to the product and what we need to screen out in our production line. It was fascinating to see how those teams worked off each other.”

From pure research to product development, D’Mello’s co-op experiences combined to help her identify her career objective: to work in biotechnology research and development of health care products.

“I like being able to work with a tangible product and go through multiple iterations to make the most effective product,” she says. “Biotechnology is an ever-evolving field and I’m really excited at the prospect of continuing to evolve into that.”