Robots face phantoms in engineering showcase on Northeastern’s Oakland campus

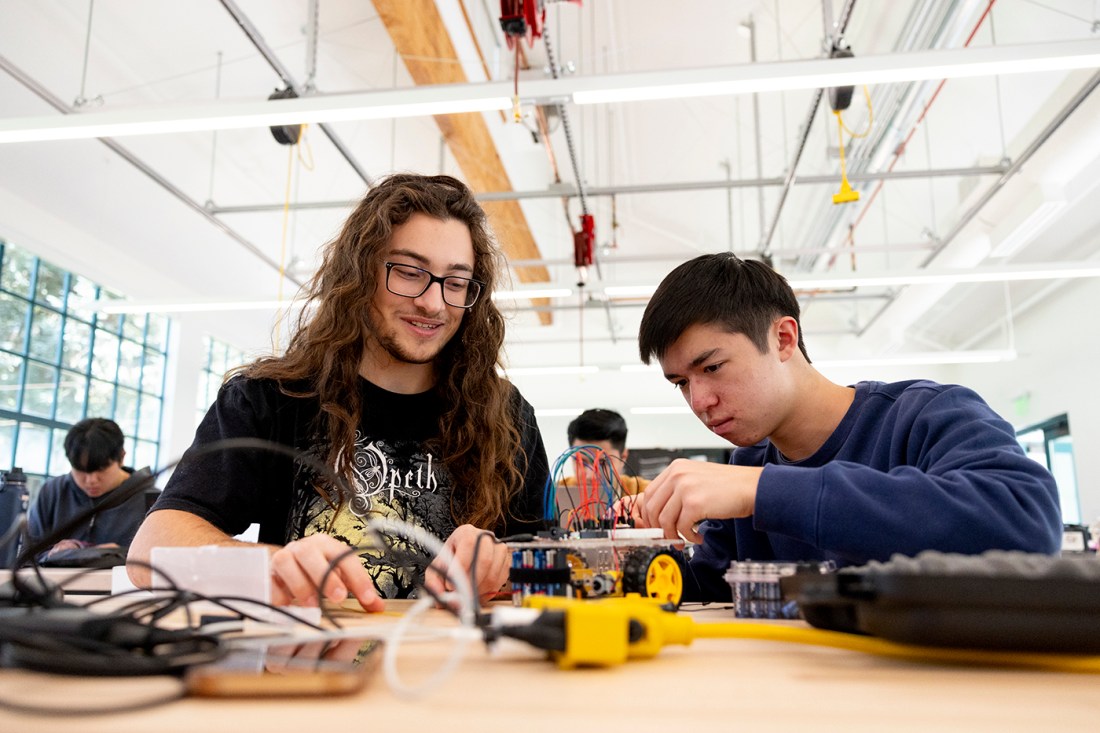

Northeastern students put their projects to the test as the robots jerked and cruised their way through cardboard mazes during the final stage of the semester’s project.

OAKLAND, Calif. — It was the phantom objects that stumped even the best-performing robots during the Cornerstone of Engineering showcase at Northeastern University’s Oakland campus.

Students recorded progress with their phones as custom-made robots jerked and cruised their way through cardboard mazes — the final stage of the semester’s project. The robot that Sebastian Leyko built with partner Aviana Fenton was doing fine until the maze challenge.

“We generally didn’t have any issues until we reached challenge three,” Leyko says. “First we had a turn issue with our robot, and then it saw phantom objects.”

In other words, the tissue box-sized machine made of a small circuit board, wheels and a battery pack came to a halt for no apparent reason.

Glitches like this are to be expected when building a robot from scratch and releasing it into unfamiliar conditions, says Leila Keyvani, associate teaching professor of engineering.

The point of the project is to challenge the small machines that students have made with new twists, turns and obstacles.

“Some robots are inconsistent,” says Keyvani, who taught Cornerstone of Engineering 1 this semester. “But they’ve done a great job with all the little intricacies.”

Other bumps along the way include motors that spin at different rates, fading battery packs and power surges when batteries are replaced.

Over the last six weeks students worked in teams of two to build robots. They put their own spin on designs using the same materials: circuit boards, wires, solderable breadboards, wheels, AA-battery packs and ping pong balls.

That last component acts like a caster wheel so the robot can move left to right. Otherwise students would have to incorporate another set of wheels. But it was proving troublesome for Alp Ayata’s robot on the third maze.

“It’s having a hard time on straightaways,” says Ayata, a bioengineering major from Hoboken, New Jersey. “The ping pong ball causes the robot to swerve a little to the left as it drives,” he says as his robot stalled out for the fourth time. “It gets to that location and it loses its traction.”

Student teams made the mazes, which each had difficulty ratings based on their turns and dead ends. The maze Ayata’s robot struggled with was a seven out of eight on the difficulty scale. Teams earned points for how their robots handle each maze — the one they made themselves, a second maze of their choosing and a third that Keyvani picked for them — and submitted a video to show how they did.

Editor’s Picks

“Once it got so close,” Ayata says, viewing a video on his phone. “It made it through the whole maze, but at the very end this back part got stuck on the wall, which stopped it from turning all the way and it got stuck at the very end. Worst case, we can submit that.”

At this final stage, there’s nothing Ayata or any of the other 63 students in Keyvani’s class can do to change their robots. But they can change the code that tells the circuit boards what to do.

Alyssa Roberts and Claire Montegut used a flowchart to create the logic structure for their robot’s code, which tells the sensors what to do under different conditions.

“That really helped us figure out how we wanted our robot to think through this maze challenge,” says Roberts, an engineering major from Boston. “It helped us guide our code.”

Gabriel Aroesty’s robot was crashing into a cardboard wall when it tried to turn right.

“It isn’t turning enough,” said Aroesty, an engineering major from Boston who, like many of the other engineering students in the class, will spend the spring semester at the London campus. “So we changed the code so it would make a longer turn.”

Try, fail, try again and fail again. That’s what engineering is all about, Keyvani says.

“The main thing for them to realize is that it’s an iterative process,” she says. “It takes time to produce and it involves programming, hardware and troubleshooting.”