This co-op in Germany is elevating her mechanical engineering — and language — skills

Teresa Schmeiszer, a fourth-year Northeastern student, is working with Hegenscheidt, an international rail-industry manufacturer.

Teresa Schmeiszer had always wanted to experience a co-op abroad. This one wound up making her feel closer to home.

Schmeiszer, a fourth-year mechanical engineering student at Northeastern University, is working in the mechanical construction team of a manufacturing company in Germany, the native country of her parents.

“I grew up speaking German at home,” says Schmeiszer, who was born and raised in New Jersey. “But this co-op has given me a whole new insight on the language because I’ve had to learn the entire technical vocabulary that comes with working in an engineering firm in Germany.”

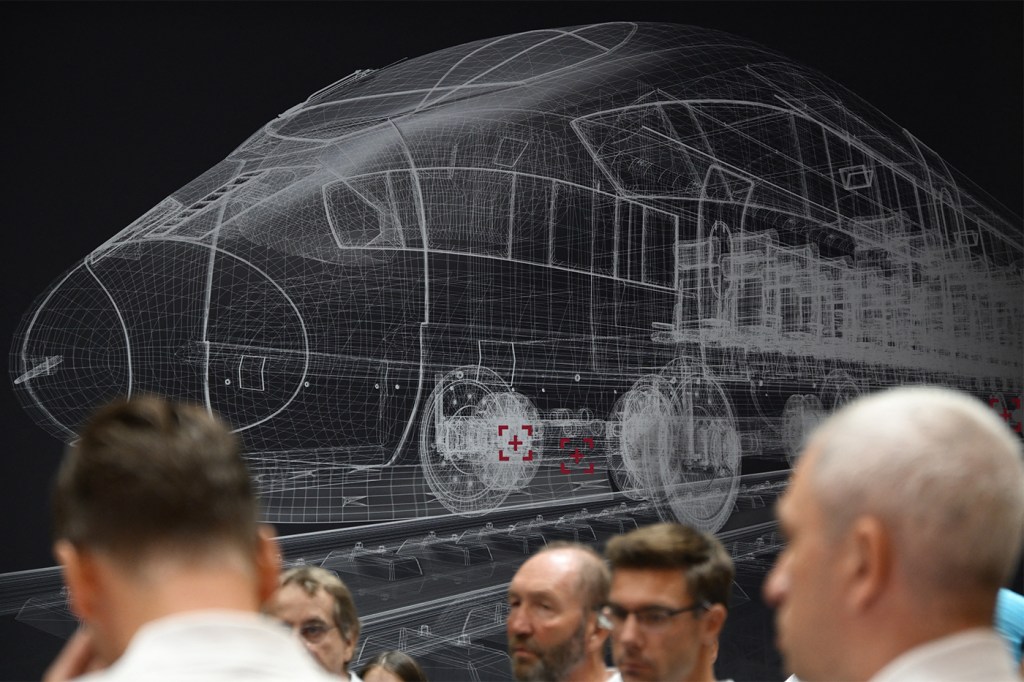

She’s on a four-month co-op with Hegenscheidt, an international family-owned business that manufactures and sells machines and turnkey production systems for the rail, automotive and engineering industries.

Schmeiszer has been working in a department that primarily designs large-scale milling machines that are used for the smoothing of worn train wheels, which increases their longevity.

“They’re one of the top global manufacturers of these milling machines,” Schmeiszer says. “Something that I’ve learned is that train track sizes vary greatly around the world — the distance between the two wheels of a train will vary.”

Those varying specs and the engineering of new approaches create a need for testing the prototypes. That’s where Schmeiszer comes in. She has been designing a measuring device that will help test the efficacy of Hegenscheidt’s developing techniques.

“I’ve been able to work on that by myself with the guidance of my manager, which has been really great,” Schmeiszer says. “I always sketch on paper first, and then all of our design is done on a 3D modeling program called SolidWorks on the computer. That’s something that I’ve had experience with at Northeastern and at my previous co-op as well — and I’ve been able to build on those skills.

“It’s an industry that’s completely new to me.”

Though she arrived with fluency in German, the co-op has been expanding her vocabulary.

“I’ve learned how to meet and communicate with new people in German so that’s been a big change,” says Schmeiszer, who commutes to work by train. “There are so many words that I’ve had to learn, but I haven’t let myself be afraid to ask questions and that has helped me grow a lot. The fluidity of my German has gotten a lot better in the two months that I’ve been here.

“Especially the first week, I was so exhausted mentally when I came home from doing my entire day in German, which is something that I’ve rarely done. I expected it but it was still surprising how much it affected me.”

Schmeiszer has been taking advantage of her extended stay in Germany by visiting with family members while also making weekend trips to Barcelona, Paris, Rome, Copenhagen and the Netherlands, whose border is near Hegenscheidt’s headquarters in western Germany.

Schmeiszer, who has been interested in the biotech and therapeutics industry, is still developing her long-term career plans.

“I’ve really appreciated having manufacturing in-house,” says Schmeiszer, who will be pursuing a third co-op in 2025. “There are so many different employees that I’ve been able to interact with — not just people who have the same background as I do, but others who work with their hands and are manufacturing the parts that we’re creating and designing. This was a once-in-a-lifetime opportunity that I couldn’t pass up and the technical growth that I’ve experienced at this company will definitely be translated into future work.”