Building a space satellite isn’t cheap. These Northeastern students are researching ways to bring the cost way down

If all goes according to plan, Northeastern University student club Project Horizon will send its first satellite into space in late 2025.

The club, which is part of AerospaceNU, is working to send a series of satellites into space as part of NASA’s CubeSat Launch Initiative, or CSLI.

Project Horizon is hoping to launch its first satellite, Pleiades-Atlas, into space next year, but has several other satellite projects in the works.

That includes a collaboration with the university’s electrical and computer engineering department to establish the world’s first sub-thz satellite network platform, which has the potential to provide high-speed internet access to remote parts of the world.

NASA’s CSLI program is designed to help and inspire educational institutions by providing them support and technical guidance to develop CubeSats — small, cube-shaped satellites used for research. In addition, NASA also provides those institutions with the launch infrastructure to actually send those satellites into space once they are completed.

But even with NASA’s assistance, developing such technologies can get expensive, often requiring components that can cost tens of thousands of dollars or more.

That’s why Project Horizon plans to reduce costs by developing some of those components itself.

The software it develops will be open-source, it says, and it will document the process online, so that other institutions can develop their own in-house parts using Northeastern’s plans.

Two students in the group were recently awarded Prototype Fund awards from Northeastern University’s Center for Entrepreneurship Education to help develop those technologies.

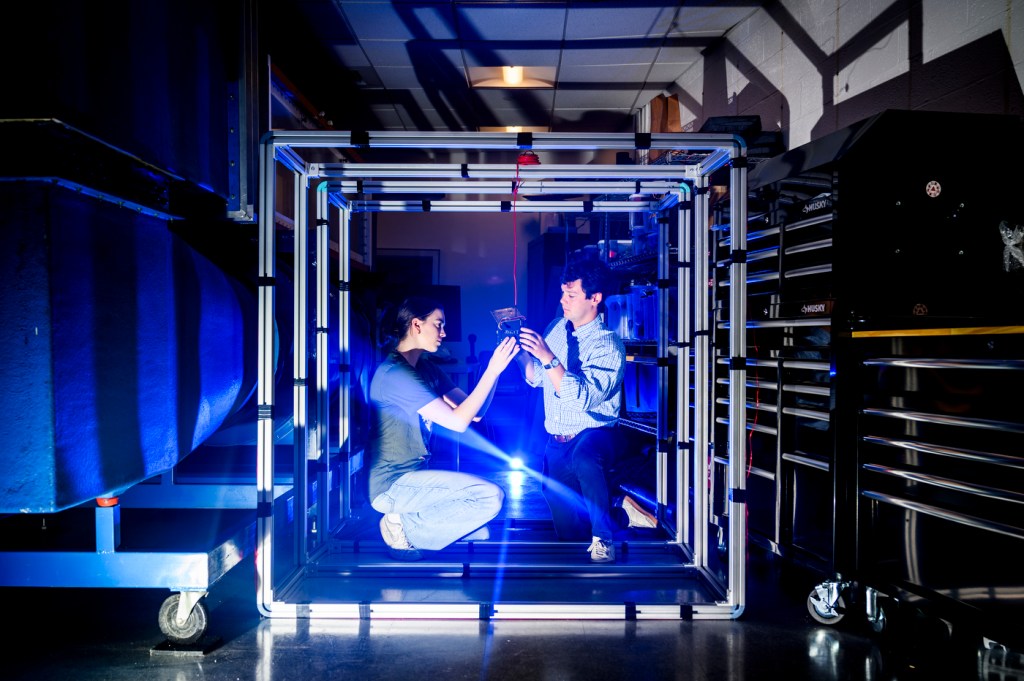

Matthew O’Rourke, a fourth-year mechanical engineering student and the space mechanics team lead for Project Horizon, is one of several students in the group. They are working on developing a more affordable 3D cage to simulate how the satellite will function in a magnetic field in space.

O’Rourke uses an analogy to play out the importance of the technology.

“If you think of chucking something out of a car at a really high speed, it’s going to be spinning uncontrollably,” he says. “That’s roughly what happens to our CubeSats when they get launched, after that we have to slow our CubeSat down and get it to detumble.”

Featured Posts

That’s where the cage comes in. The cage is composed of a number of magnetic coils that can be used to slow the satellite down and steer it.

“You can buy these online for around $10,000,” he says. “We are on target right now, to do it for closer to $5,000. That’s still really expensive, but what we are doing with this is that we are making it a lot easier to put together, a lot easier to disassemble, and we’re making it all open source, so we’re publishing how we did it”

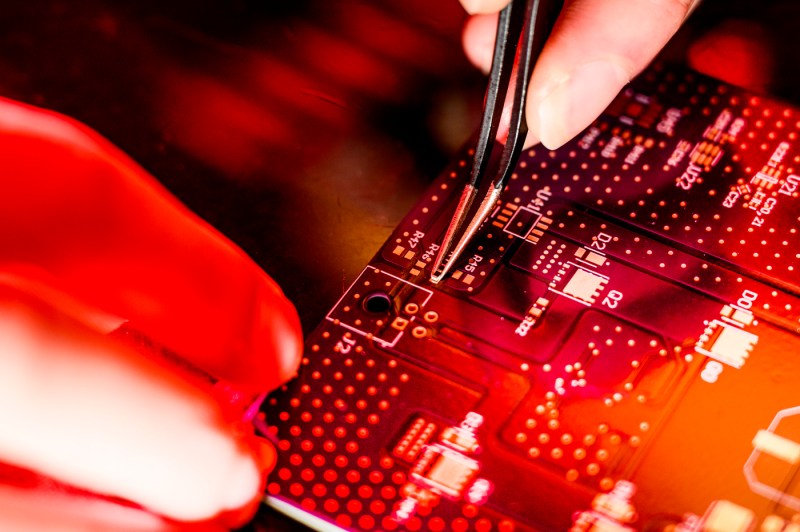

Rachel Rakushkin, a third-year electrical engineering student and a member of Project Horizon, is one of several Project Horizon students working on developing a cheaper form of s-band communication.

S-band communication is a high-speed type of communication system used to interact with satellites that take advantage of frequency bands in the electromagnetic spectrum.

S-Band communication transmitters can easily cost $15,000, Rakushkin says. Commercial solutions are often very expensive because they provide a high Technology Readiness Level number, or TRL, a 9-level measurement score that NASA and other agencies use to determine the maturity of a technology, she says.

Technology that has been proven to work in space flight is given a level 9 TRL score, while a technology that is still just theoretical is given a level 1 TRL score.

By cutting down on the complexity of commercial products, and developing a S-band communication system in-house, Rakushkin estimates the project can be completed at a fraction of the price.

“The final product if you are just looking for all the resources and components, and the manufacturing that alone should be for sure under $500,” she says.

O’Rourke says that the undertaking is both “very fulfilling and also very scary,” given the stakes involved with developing technologies that will go into space.

“If you are building an underwater robot, to test yours all you have to do is throw it in a pool. If you’re building a car, you can go drive it on the street,” he says. “We can never test to that same level, we can’t put our thing in space for 15 minutes and get it back after. What that means is the engineering has to be a lot better, and that it can’t fail.”