Northeastern researchers innovate optical microchips with applications for sensing and communications

Infrared light cannot be seen, but it can be felt as heat. Lying beyond the red color in the electromagnetic spectrum, it is used by animals to detect prey in the dark and in night vision cameras.

Infrared spectroscopy, which explores how infrared light interacts with matter, has played a pivotal role in helping researchers advance in a range of domains, including drug testing, material science and environmental monitoring — just to name a few.

Research in this field has often involved the use of expensive instruments that cost in tens of thousands of dollars due to the use of broad, heavy, and bulky light sources and detectors.

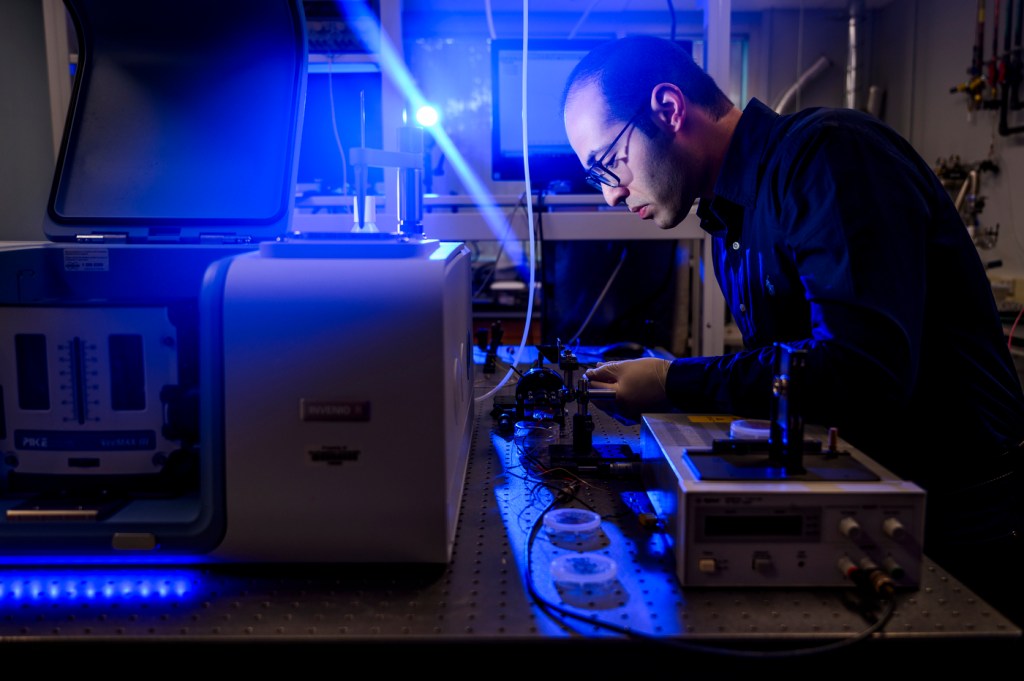

But new optical chips being developed by researchers in Northeastern University’s Computer and Electrical Engineering Department are promising to bring down those costs and the size to palm top instruments.

Featured Posts

“At this time, if you want to do this type of spectroscopy, you have to use equipment that is very large and bulky,” says Northeastern professor Srinivas Tadigadapa, one of the researchers behind the chips. “What we have done by miniaturizing these sources and making them chip-scale, it will be possible for us to (one day) get them into cell phones or other smart devices of the next generation.”

Tadigadapa and Soheil Farazi, a doctoral student in Tadigadapa’s lab, have utilized advanced quantum mechanical techniques to develop the technology.

One of the primary methods they used involved a quantum physics concept known as a bound-state in the continuum (BIC). This approach leverages specific wave patterns and resonances within a structured material to create chips capable of generating coherent, single-wavelength light sources akin to lasers.

“What we are doing here is not using a laser, but we are able to create laser-like light with a chip that is just heated on a hot plate,” Tadigadapa says.

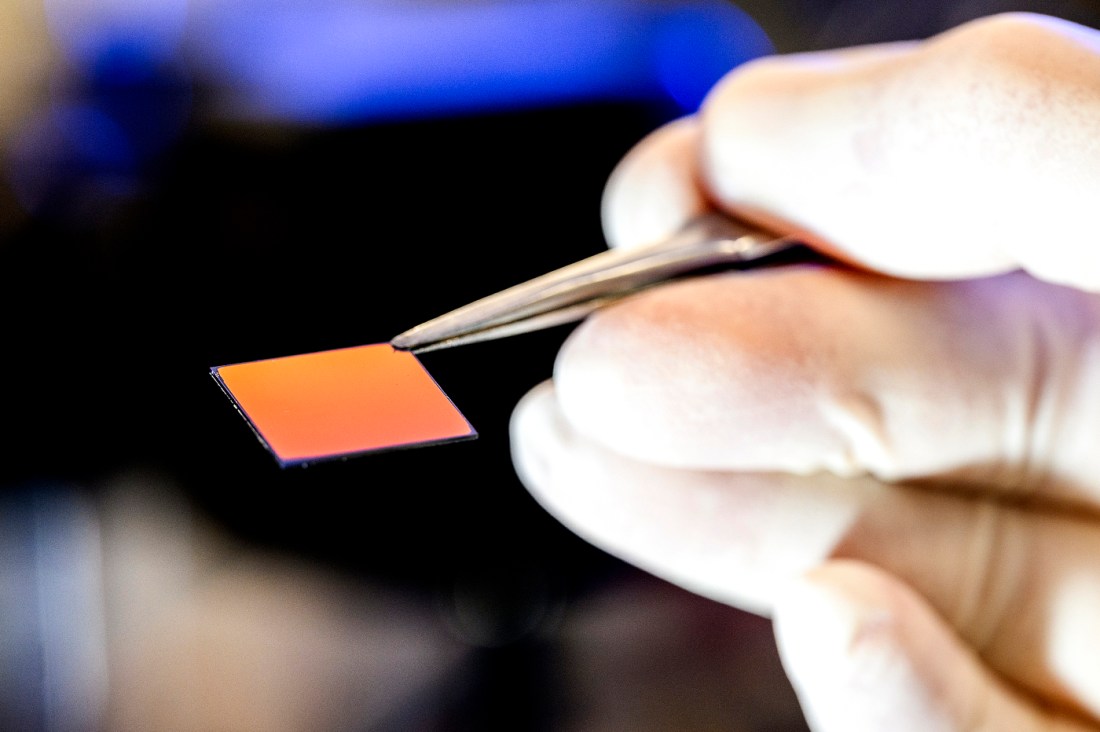

“The materials we are using are really straightforward and easily accessible. The process by which we make this device is elegantly designed,” adds Tadigadapa, noting that once these chips can be mass-developed they can be produced at a minimal cost.

The optical chips are capable of generating light in the 10 to 12 micrometer in the mid-infrared range, which Tadigadapa says is an important range for molecular detection and analysis.

Farazi adds that coherent single-wavelength sources are essential for a range of sensing and wireless communication technologies as light sources that emit too many wavelengths are not desired and can complicate signal interpretation.

The researchers are in the early stages of developing the technology, focusing on enhancing the chip’s tunability and improving the precision of its emission characteristics.

But they have successfully completed the challenging initial design and fabrication phase of the chips, says Tadigadapa, which they manufactured in Northeastern’s Kostas nanofabrication facility in the Egan Research Center on the Boston campus.

“This is the first brick in the wall we are going to build,” he says. “Without this brick, the wall will never be made.”