Inside the lab that tests Northeastern for the coronavirus

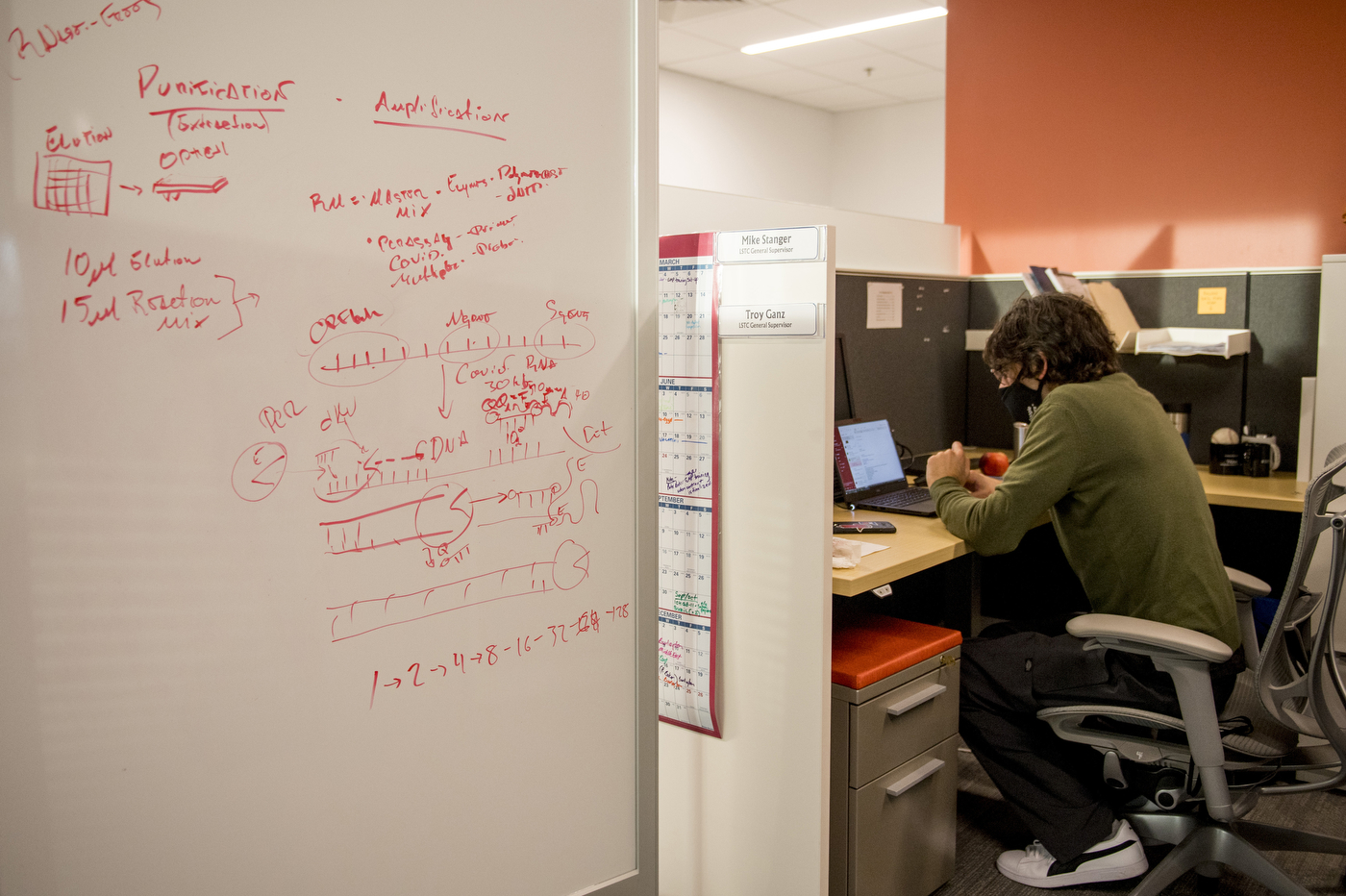

BURLINGTON, Massachusetts—Troy Ganz is one of the scientists at Northeastern’s Life Sciences Testing Center, who helps the university process thousands of coronavirus tests every day. We followed Ganz on a typical day to see how a massive testing operation turns around thousands of results in less than a day.

Photos by Matthew Modoono/Northeastern University

It’s 5 a.m. on a quiet and cool morning when Troy Ganz arrives at the Life Sciences Testing Center in Burlington, Massachusetts. As one of the general supervisors in the lab, Ganz provides support and oversight for dozens of scientists who process COVID-19 tests every day.

The day’s first rays of light brighten the backdrop at Northeastern’s Innovation Campus, which houses the Life Sciences Testing Center. Since its official opening in August, scientists at the lab have been working around the clock to conduct the high complexity molecular analysis that ensures test results are produced fast and accurately. The lab is open 24 hours a day in order to process thousands of tests every day.

Inside the building, a skeleton crew of scientists who worked overnight awaits Ganz and other scientists to kick off the day’s testing. The night crew has been inside the lab preparing the chemical solutions, machines, and instruments needed on a daily basis to test for the presence of SARS-CoV-2, the coronavirus that causes COVID-19.

In addition to training new scientists joining the lab, supervisory scientists such as Ganz oversee a complex operation that relies on several critical steps. Scientists first need to extract the coronavirus’ genetic material from the dry cotton swabs that people use to sample their nostrils. Then they conduct molecular analysis to spot viral infection.

The lab has grown dramatically since Ganz joined the team in July. The space includes more than 1000 square feet where scientists prepare and analyze samples. The facilities also rely on an adjacent warehouse full of parts, supplies, and chemical solutions, as well as personal protective equipment and disinfectants. Abundance of these supplies is essential to sustain an operation of this magnitude.

Ganz makes the rounds within the lab several times during the day to ensure a smooth workflow. Wearing personal protective equipment is always critical—but not just to avoid transmission of the coronavirus during the pandemic. The gear also helps to prevent contamination of the samples. It’s important for all lab staff to use aseptic techniques that ensure the cleanliness of their equipment and lab benches in order to avoid introducing impurities that could hinder the ability of the instrumentation to detect the coronavirus in a sample.

Ganz has been part of the operation since July, when Northeastern rallied scientists in the Burlington campus to set up a lab with the capability to test large numbers of coronavirus tests consistently—and acquire the state and federal licenses to operate. The lab has been running at full capacity since Aug. 17, completing more than 300,000 tests since then. Some of those results were processed by the Broad Institute, a biomedical research center in Cambridge, Massachusetts.

The tests scientists perform every day in the lab have an accuracy of more than 99 percent thanks to a specialized method that detects the virus’ RNA, which is similar to DNA in humans, to spot infection. This kind of testing, Ganz says, relies on complex instrumentation and the skills of lab technicians. Different chemical solutions extract and break down the biofluids swabbed from a person’s nostrils, including the viral material if it’s present. Picture it like this, Ganz says: The virus’ genes are like salt in a glass of Gatorade. To get that salt ready for molecular analysis, scientists need to treat the liquid through different steps to separate its other components, such as sugar or food coloring.

The team Ganz oversees consists of former medical lab technicians, physicians, and other scientists with experience working in medical laboratory settings. New lab members are fully integrated into the operation by their second week, and master each step of the testing process, so they can rotate and work on different stations according to the needs of the lab.

Machines in the lab are running non-stop, and need to be monitored and checked constantly. Every day, Ganz ensures that lab instruments work properly and monitors the temperatures of freezers and fridges that hold important chemical reagents and other solutions.

The mornings are quiet for Ganz and the lab until 9 a.m., when more scientists arrive to kick off the day. To promote the safety of lab staff, a coronavirus test is required of everyone, every day.

The first batch of tests from the Boston campus arrives shortly after 9 a.m. via a medical courier. The samples come from the Cabot Physical Education Center, which was retrofitted earlier in the pandemic to allow for thousands of people living and working on the Boston campus to receive a test regularly, any day of the week, if they do not show symptoms of COVID-19.

More batches arrive throughout the day with hundreds of tests until later in the evening, when collection ceases in the Boston campus. These samples also include tests from Northeastern’s Huntington Testing Center, where people with symptoms of COVID-19 get their tests.

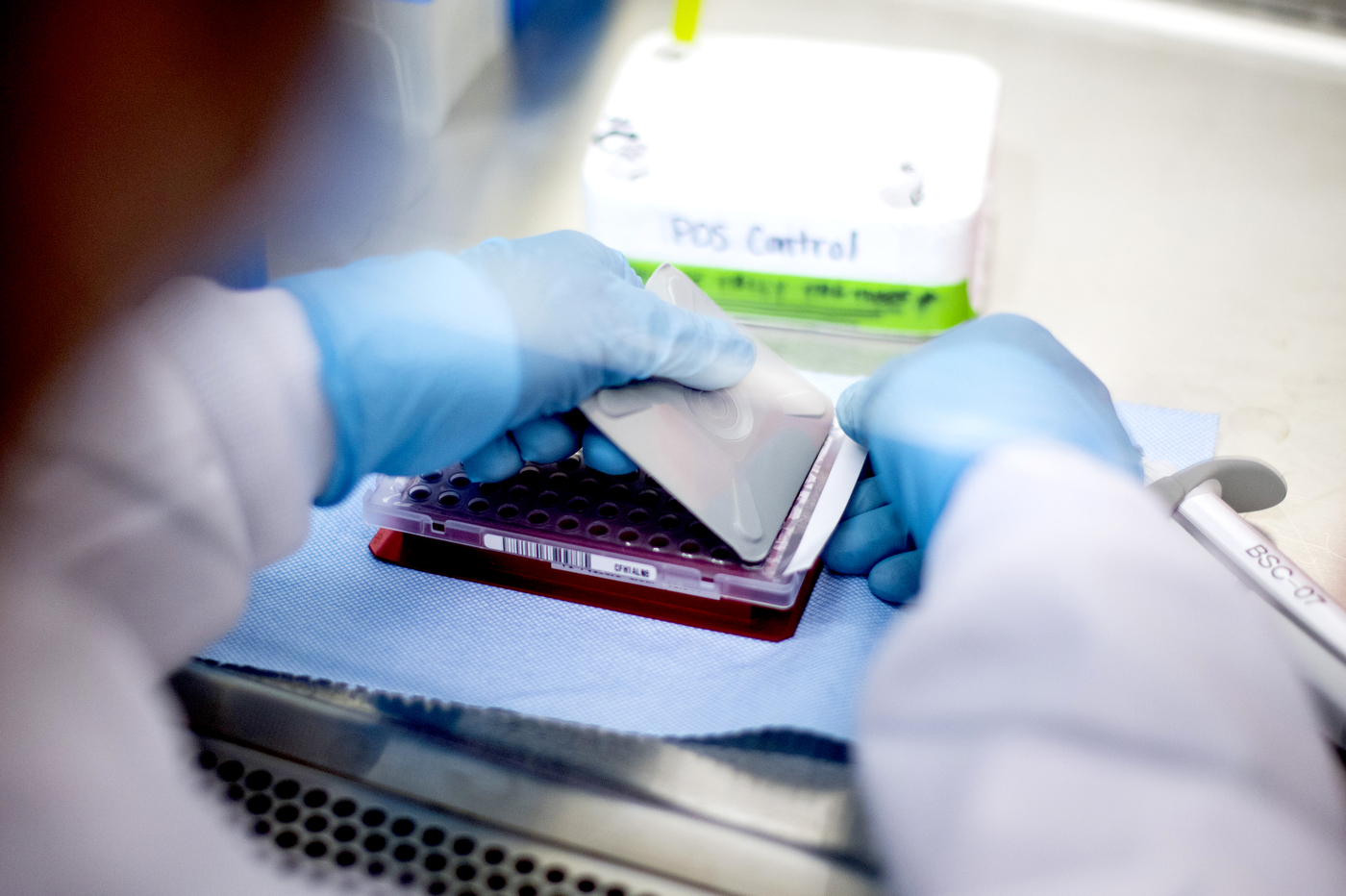

The first step after tests arrive is logging each of the vials into the lab’s records. This step, known as accessioning, is crucial in the operation because the scientists create a system that will map and identify each sample as it passes from station to station in the lab.

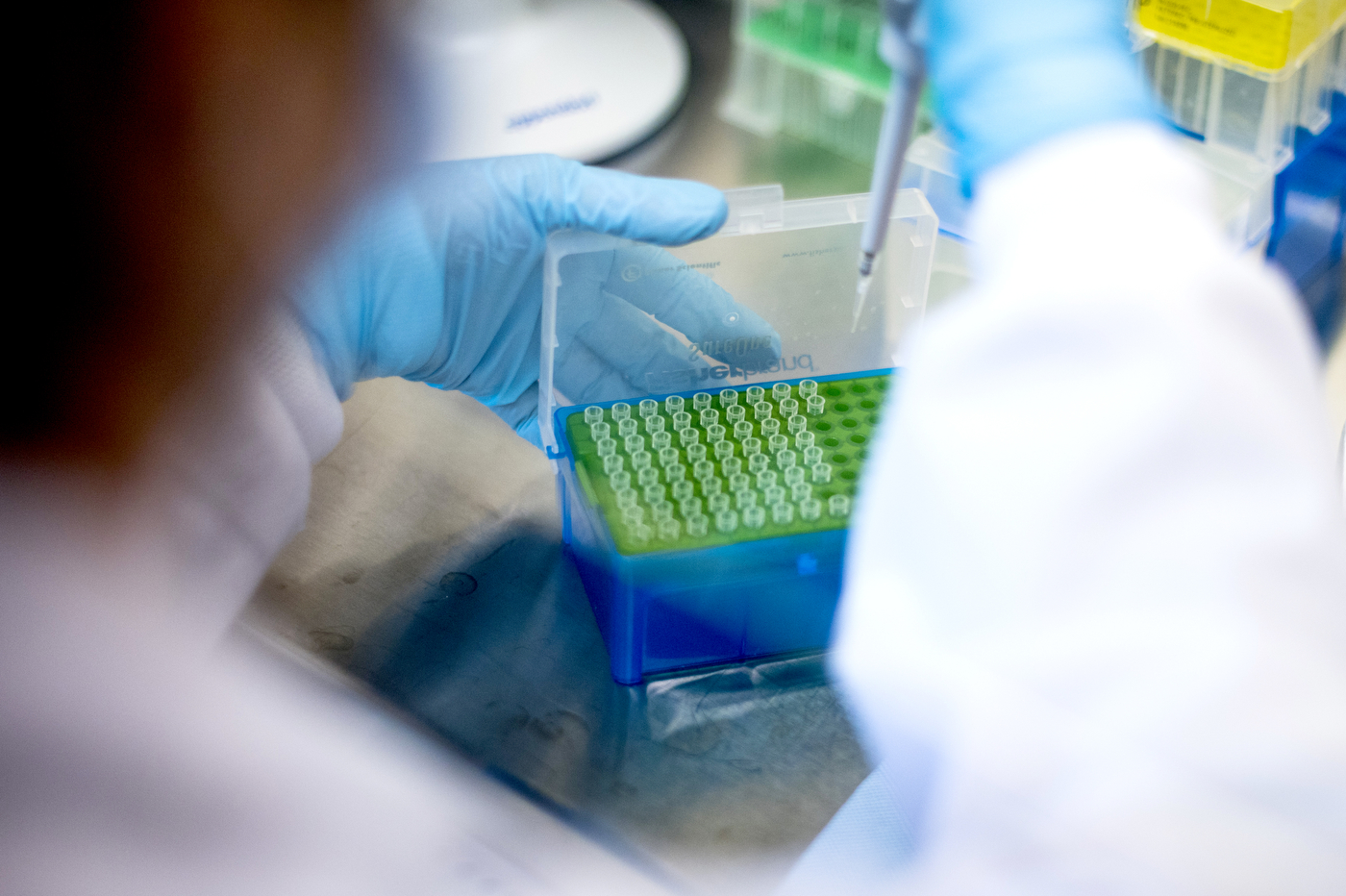

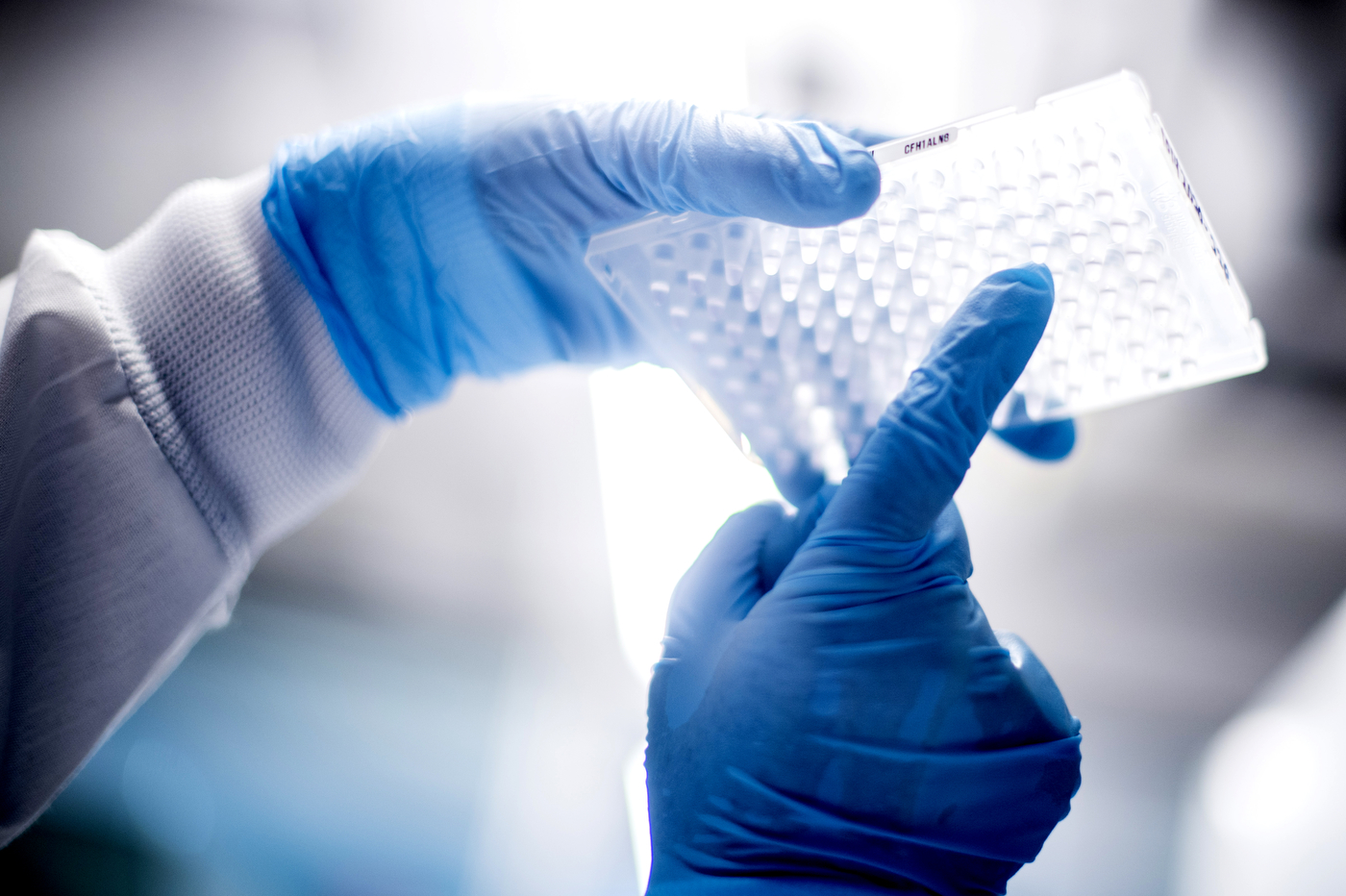

Accessioning is important because all samples are organized using 96-well plates. These racks have 96 positions that function as coordinates in a map to identify each sample over its entire journey through the lab. Using the plate map system ensures the accurate delivery of results, because the samples will be moved to different 96-well plates during the prepping and purification process leading to molecular analysis.

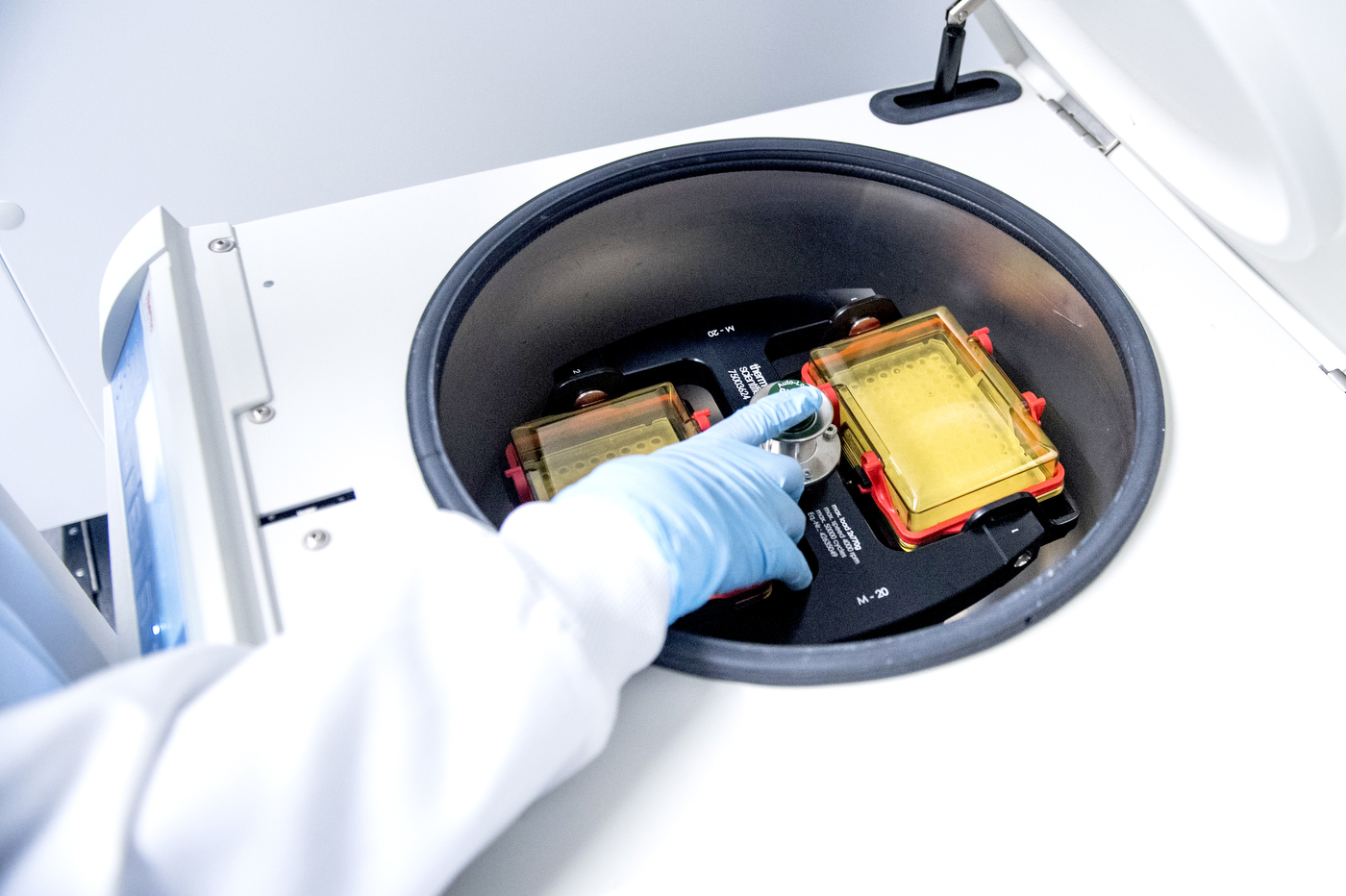

Robotic machines that handle liquid samples help speed up the process of preparing solutions for analysis. Under the supervision of Ganz and lab technicians, 13 of these instruments subject the samples to shaking and heating. The robotic machines also wash the samples with a mix of chemical solutions and nano-sized magnetic particles that will purify any potential molecules of the virus’ genetic materials. The aim is to remove any human tissue, waste proteins, or lipids, which would interfere with the molecular analysis once the virus is broken up to release its RNA.

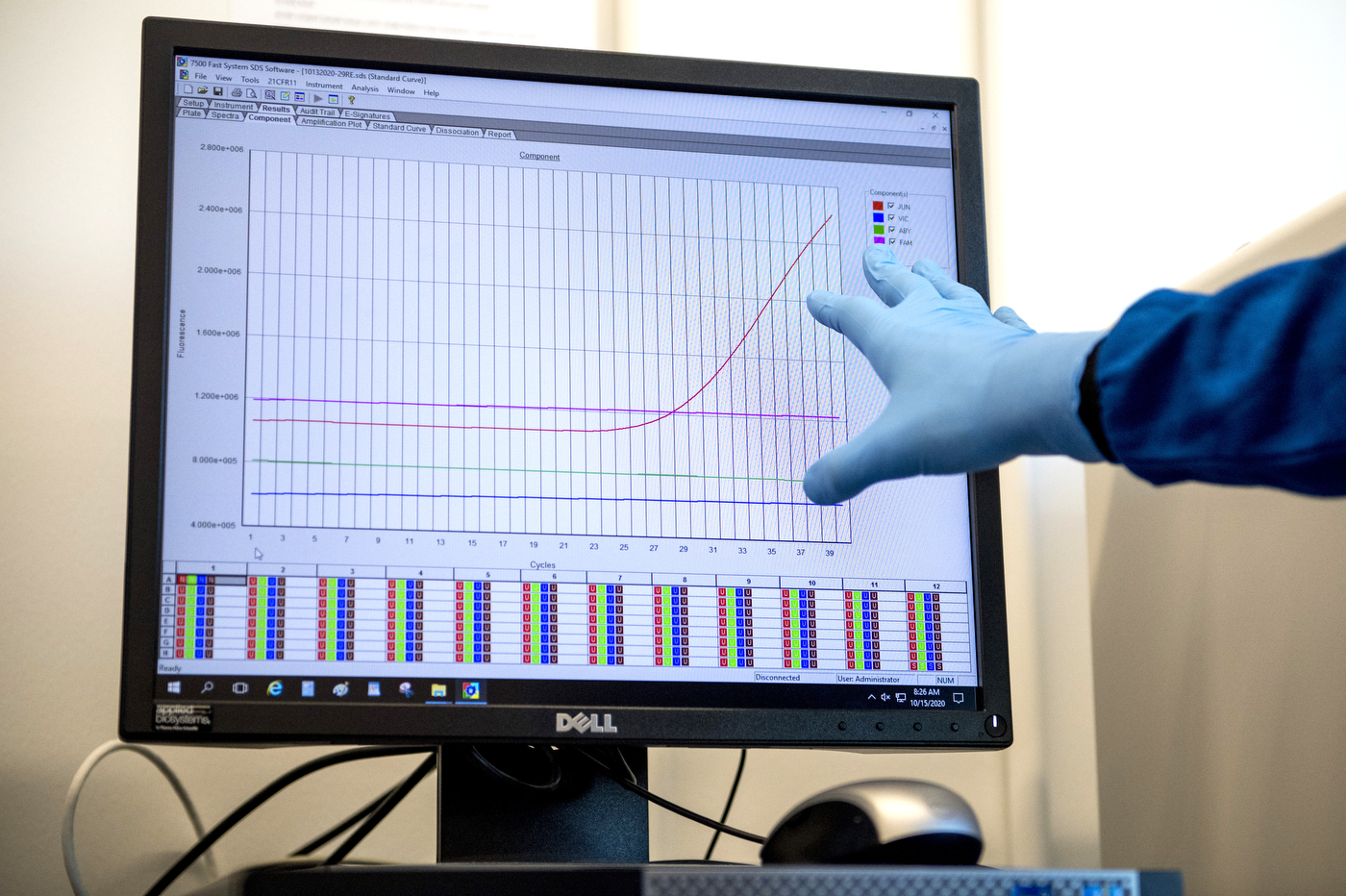

Scientists use the purified solution to perform a technique called polymerase chain reaction, or PCR, which is commonly used in molecular biology research to make billions of copies of DNA fragments. To do that, the virus’s RNA needs to be converted into clonal DNA using a special enzyme called reverse transcriptase. Then, scientists add different enzymes that cause the DNA to replicate exponentially, amplifying it to a level that can be detected.

PCR is known as the gold standard in viral testing because it allows scientists to test for specific genes from SARS-CoV-2. At Northeastern’s lab, the PCR machine’s detector looks for the presence of three of the coronavirus’ genes. As an extra step to ensure the high accuracy of Northeastern’s results, and to avoid false positives, scientists make sure to repeat the molecular analysis if only one or two of the genes from the virus are detected.

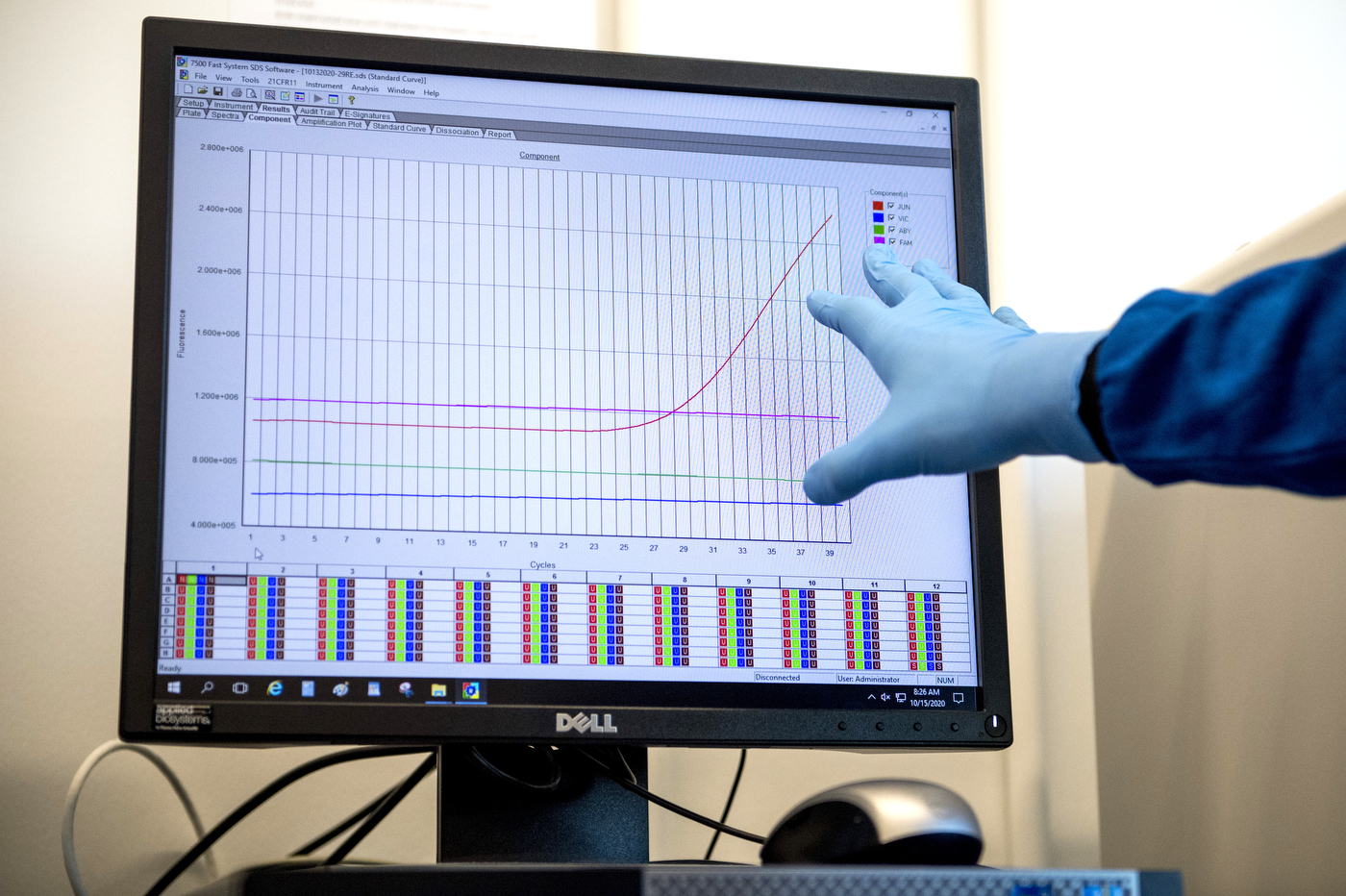

If a coronavirus gene is present and amplified, specially engineered probe molecules will glow, giving a signal of brightness, depending on the viral load within the sample. This “fluorescent event” signals the presence of three of the coronavirus’ genes.

A negative test shows a graph with no peaks to indicate detection of the three target coronavirus genes. But to ensure that the lab meets the expectations for accurate results, scientists also add a control gene to look for, which must always show a peak in the graph. If the signal of that gene shows no fluorescence, scientists can be confident that instead of a negative result, the graph shows a fault in the process of extracting the virus’ RNA during the purification stage, and the tests need to be re-run.

The entire process, from when a sample arrives at the lab to when results are reported, generally takes between three and four hours. That cycle of testing goes on after Ganz leaves at 5 p.m., as other supervisors and technicians keep the lab running at full speed until midnight, and on until the next morning. By then, the lab will have produced well over 5,000 results.