The man behind the machine behind the masks

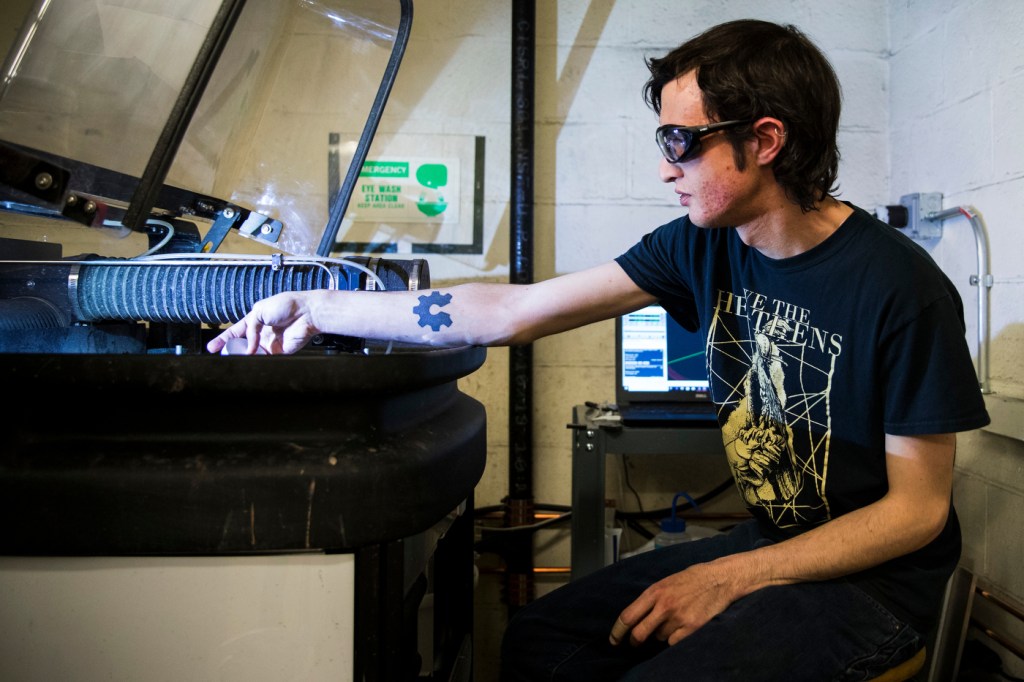

When Northeastern’s Boston campus moved to online instruction in March in accordance with guidance from public health agencies, Ben Macalister, a senior machinist in the department of mechanical and industrial engineering, needed to find something to do with his hands.

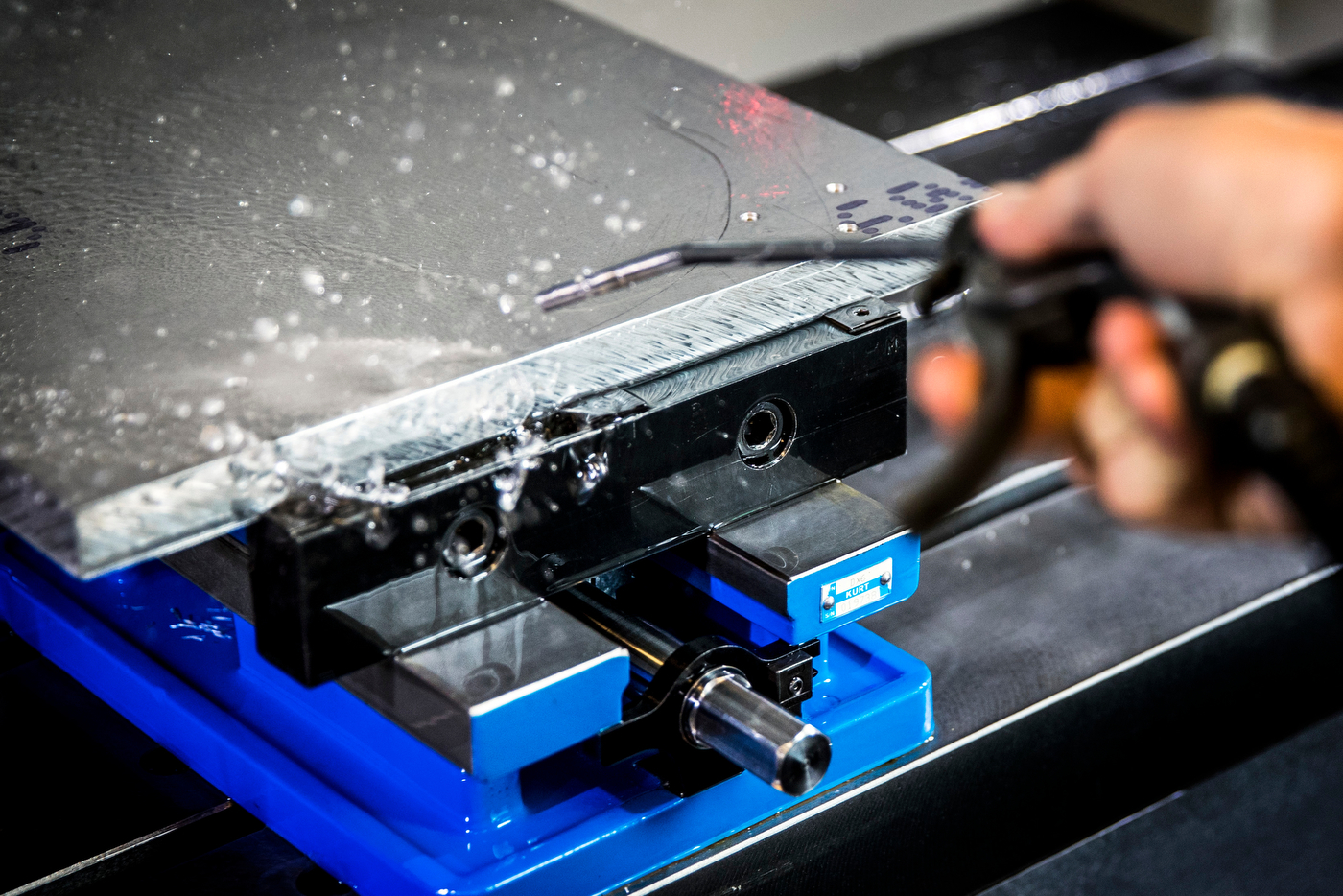

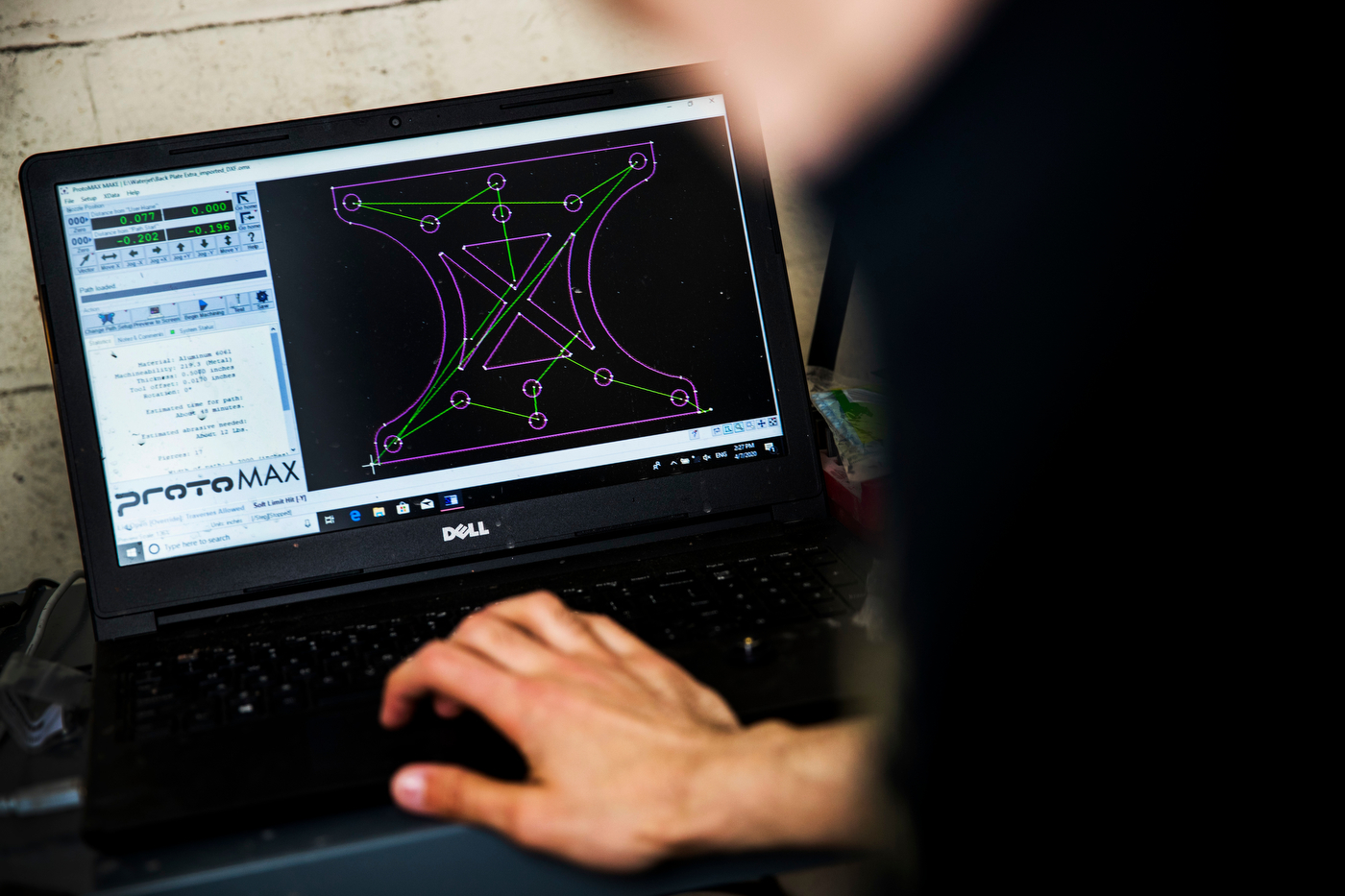

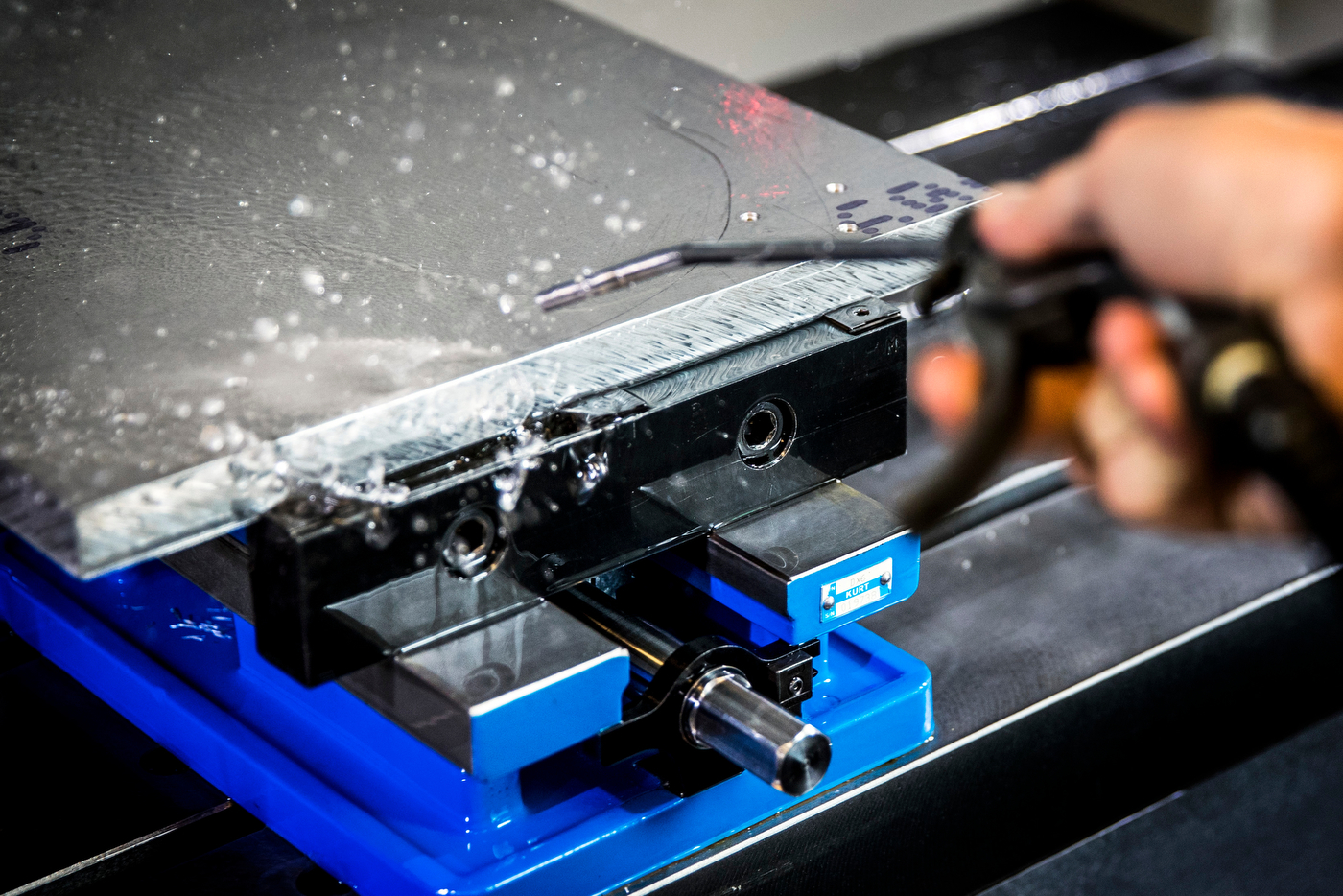

Macalister has been using Northeastern’s machine shop in the Forsyth building to manufacture parts for machines that will build protective gear for hospital workers.

His work is part of a larger effort led by Artisan’s Asylum, a non-profit community fabrication center in Somerville, Massachusetts. The group is working with several local healthcare providers to ensure that they have enough face shields, gowns, and masks to stay protected while they care for patients with COVID-19.

Macalister is currently working with the team making surgical masks. His job includes manufacturing a device to pleat mask material and a mount to hold a plastic spot-welder used to attach the elastic bands.