Northeastern unveils second-generation nanoscale manufacturing system

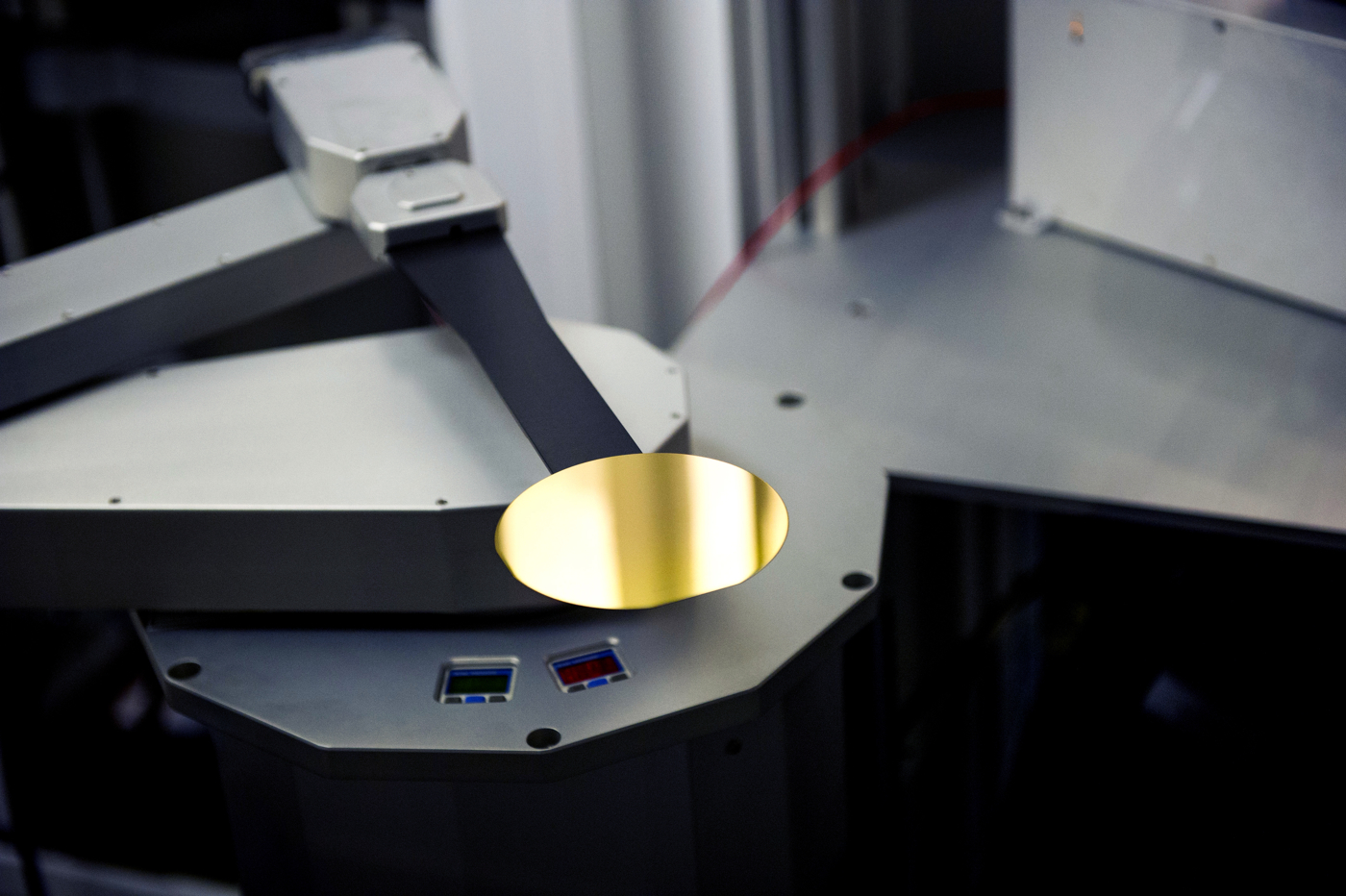

Northeastern on Wednesday unveiled NanoOPS Gen 2, the university’s second-generation-nanoscale offset printing system. The pioneering manufacturing technology is designed to drive innovation in fields such as medicine, electronics, and energy storage.

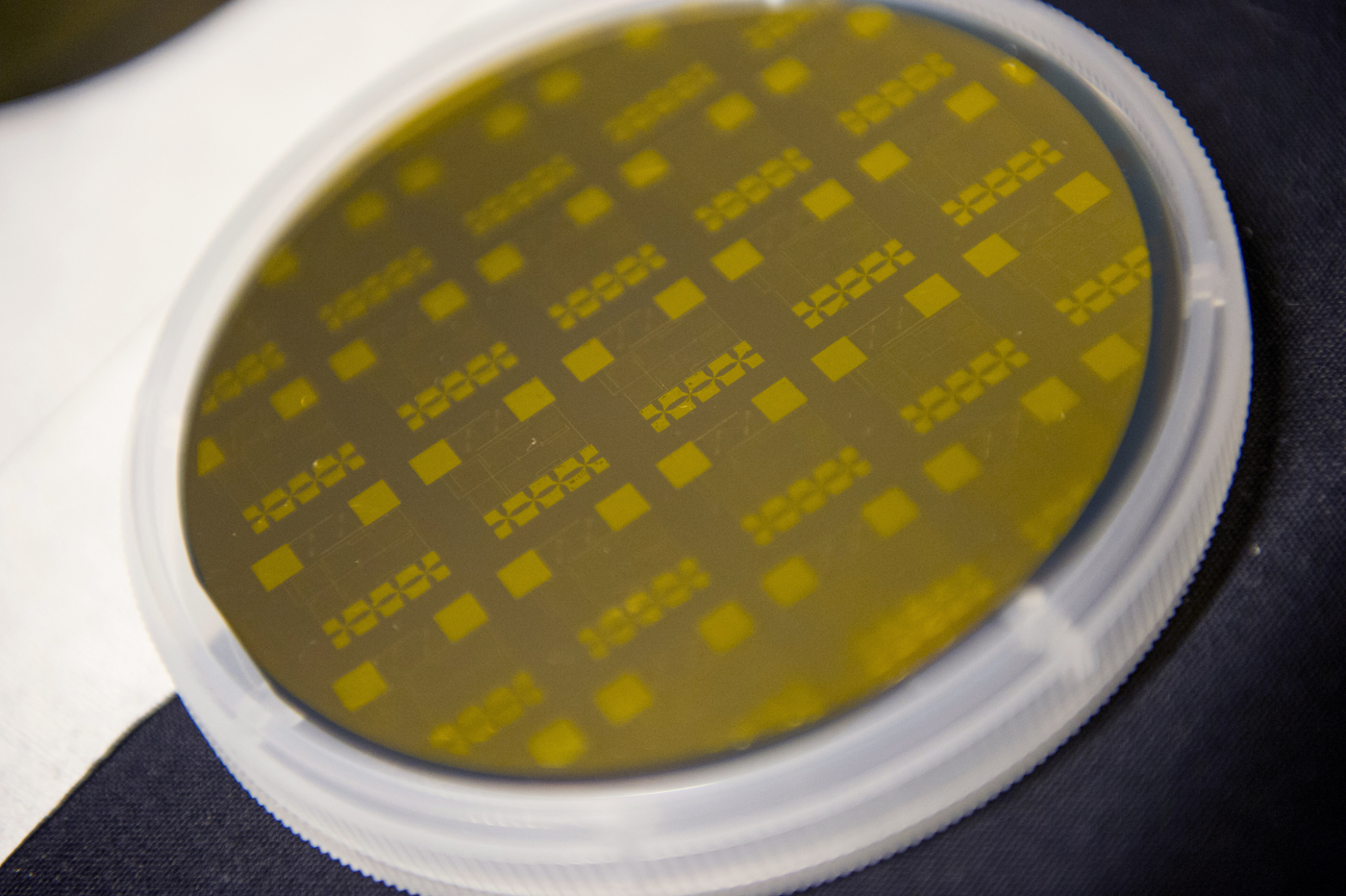

NanoOPS Gen 2 is housed at the George J. Kostas Research Institute for Homeland Security at the university’s Innovation Campus in Burlington, Massachusetts. It can print 1,000 times faster and 1,000 smaller circuits—down to a 20 nanometer—than inkjet-based printing systems on the market today, according to Ahmed Busnaina, University Distinguished Professor and the William Lincoln Smith Chair Professor in the College of Engineering.

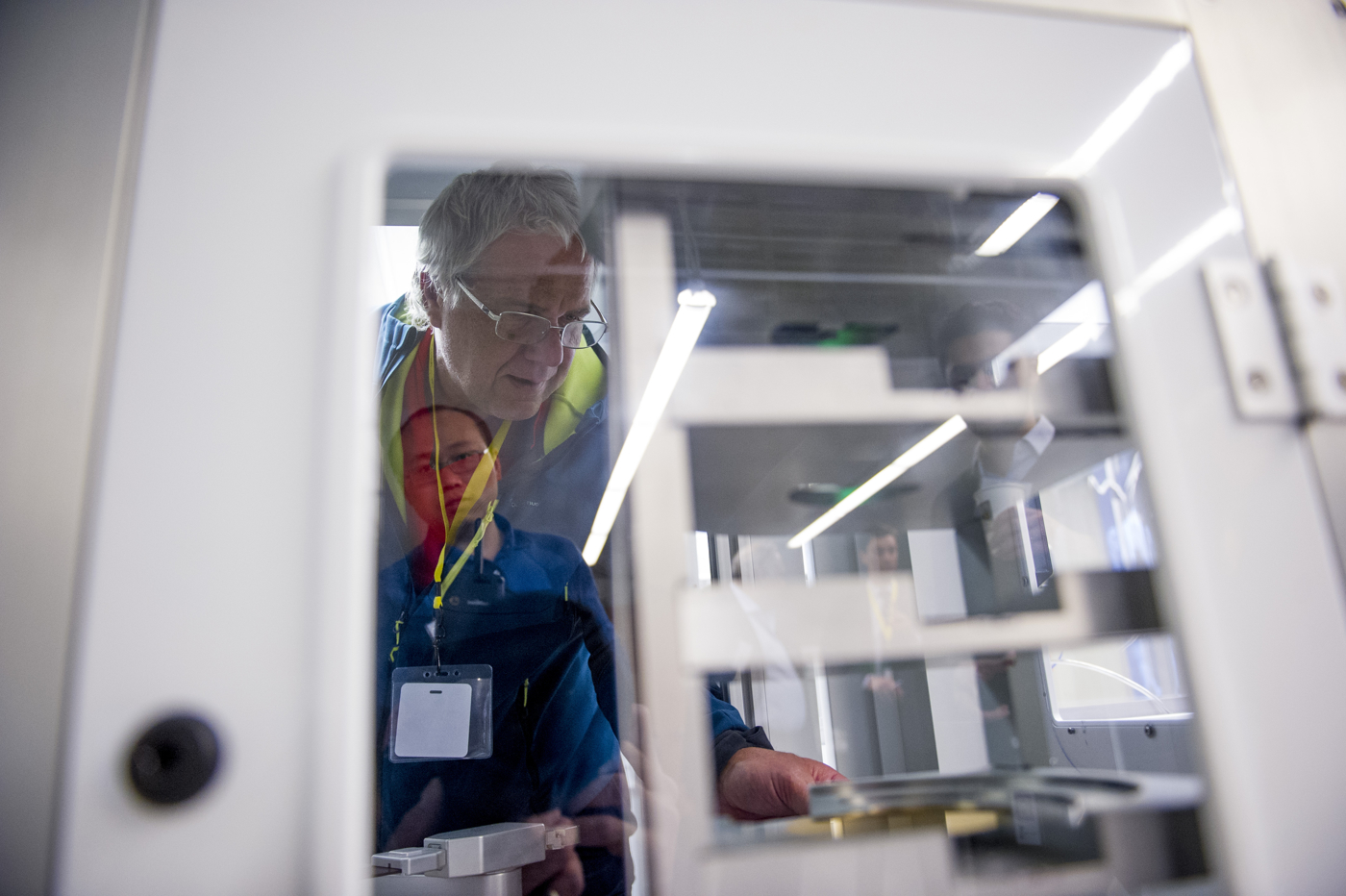

University leaders and researchers joined representatives from industry and government agencies at the unveiling ceremony in Burlington.

Busnaina, who directs Northeastern’s Center for High-Rate Nanomanufacturing, said this second-generation system is modular and can print multiple layers at a time and on larger substrates than the first NanoOPS. The abilities to use a wider variety of organic and inorganic materials and have much more precise control of the manufacturing process are among other advances from the first version unveiled three years ago.

Busnaina said researchers are using NanoOPS to develop a variety of materials for industry partners, from biosensors, to medical implantable devices, to electronics. In one project, they are developing sensors for California-based Flex that monitor athletes’ glucose levels through their sweat.

Northeastern collaborated with Massachusetts-based Milara Inc., to design NanoOPS Gen 2.

The system was developed through Northeastern’s Advanced Nanomanufacturing Cluster for Smart Sensors and Materials, directed by Busnaina and established last year through a state grant from the Massachusetts Technology Collaborative’s Collaborative Research and Development Matching Grant Program. That grant was matched by nearly $11 million in outside funds between academia, industry, and government.

David Luzzi, vice president for the Northeastern University Innovation Campus and vice provost for research innovation and development, said NanoOPS Gen 2 is the latest example of the vision to establish partnerships between academia, industry, and government to advance technology for the nation’s benefit. “Partnerships have become absolutely core to the new DNA of this campus,” he said.

Patrick Larkin, director of the Innovation Institute at the Massachusetts Technology Collaborative, also underscored the value of such partnerships. He called NanoOPS Gen 2 “a revolutionary piece of equipment which will build the next-generation of smart sensors, materials, and electronics.”

“Northeastern really is an institution that understands the meaning of R&D,” Larkin said, “[and] allows researchers to explore the frontiers of science and engineering while at the same time keeping an eye on practical applications for the world.”