‘Small’ transformation yields big changes

An interdisciplinary team of researchers led by Northeastern University has developed a novel method for controllably constructing precise inter-nanotube junctions and a variety of nanocarbon structures in carbon nanotube arrays. The method, the researchers say, is facile and easily scalable, which will allow them to tailor the physical properties of nanotube networks for use in applications ranging from electronic devices to CNT-reinforced composite materials found in everything from cars to sports equipment.

Their findings were published on Monday in the journal Nature Communications. The paper—titled “Sculpting carbon bonds for allotropic transformation through solid-state re-engineering of -sp2 carbon”—was co-authored by postdocs, students, and leading CNT researchers from Northeastern University, the Massachusetts Institute of Technology, and the Korea Advanced Institute of Science and Technology whose expertise runs from physics and mechanical engineering to materials science and electrical engineering.

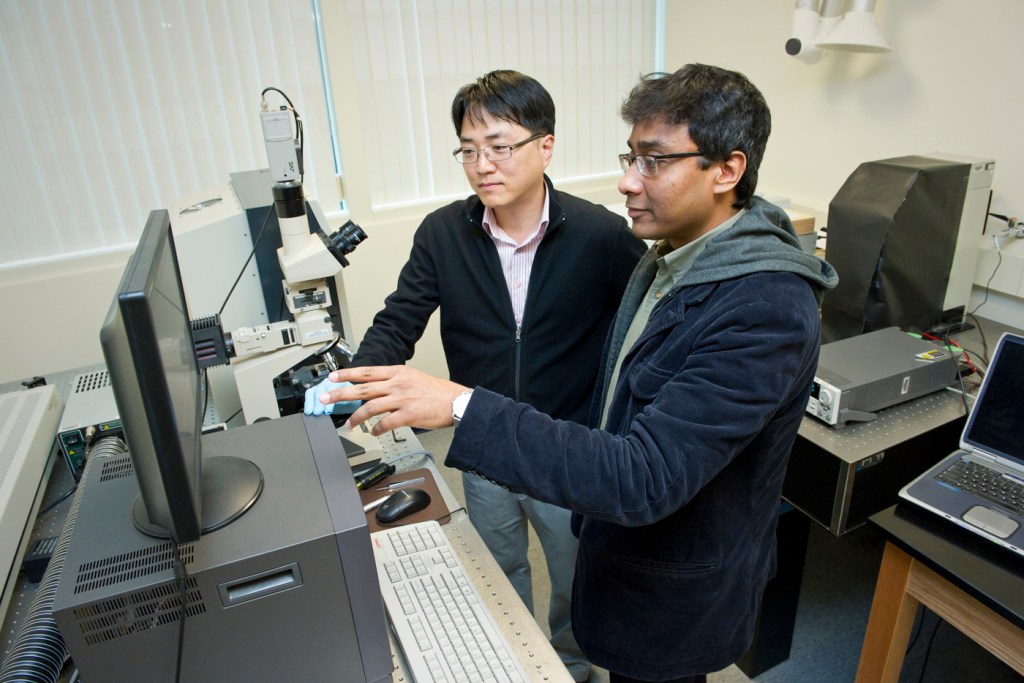

The chief architect of the team’s novel method for re-engineering carbon bonds was Hyunyoung Jung, the paper’s lead author and a postdoctoral fellow in the lab of co-author Yung Joon Jung, a nano-manufacturing expert and an associate professor of mechanical and industrial engineering.

Hyunyoung found that applying controlled, alternating voltage pulses across single-walled carbon nanotube networks transformed them into larger-diameter single-walled CNTs; multi-walled CNTs of different morphologies; or multi-layered graphene nanorribbons.

The new reconstruction method—unlike previous attempts to meld nanotubes—eschews harsh chemicals and extremely high temperatures, making the solid-state engineering technique eminently conducive to scalability. What’s more, the new method produces molecular junctions whose electrical and thermal conductivities are far superior compared to the junction-free assembled CNT network.

Their robust physical properties, the researchers say, make these inter-nanotube junctions perfect for reinforcing composite materials that require mechanical toughness, including tennis racquets, golf clubs, cars, and even airplanes, where carbon fibers are currently being used. “Using these materials for mechanical components could lighten cars or other mechanical structures without sacrificing strength,” Yung Joon explained.

The researchers described the utility of their groundbreaking work through the use of a metaphor in which carbon nanotubes were wall-building bricks. Fashion a wall by stacking single bricks atop each other, they said, and watch the wall come tumbling down. But build a wall by placing cement between the bricks and marvel at the indomitable strength of the larger, single unit.

“We have filled in the gaps with cement,” said co-author Swastik Kar, an assistant professor of physics at Northeastern, in keeping with the metaphor. “We started with single-walled carbon nanotubes,” he added, “and then used this pioneering method to bring them together.”

In addition to Kar, Hyunyoung, and Yung Joon, the paper’s Northeastern co-authors comprised Younglae Kim, an ex-graduate student, and Sanghyung Hong, a doctoral candidate in Yung Joon Jung’s lab. “Professor Kar’s and our groups have had a very strong collaboration for many years,” Yung Joon said. “This research brings together experts from a number of disciplines to not only produce a high-impact paper but also to generate intellectual property.”

The team’s research was supported by the National Science Foundation and the Ministry of Industry in the Republic of Korea.